Mastering Efficiency: A Guide to Unitized Wall Systems

Time and quality are the currencies that define success in the rapidly evolving world of construction. For construction professionals and project managers continually seeking methods to streamline processes without compromising on standards, unitized wall systems offer a solution that seems almost too good to be true.

Understanding Unitized Wall Systems

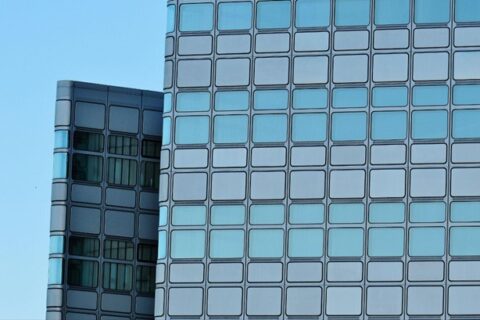

At their core, unitized wall systems are pre-assembled walls – including the framing, insulation, cladding, and even windows – constructed in a factory setting before being transported to the construction site ready for installation. This approach contrasts traditional building methods, where each component is assembled bit by bit on site.

Here are the key benefits that make unitized wall systems a game-changer for the construction industry:

Faster Installation

Time is a crucial factor in construction projects. Delays can lead to increased costs and resources, not to mention unhappy clients. Unitized wall systems can be installed much faster than traditional construction methods. Since walls are pre-made, the need for multiple trades on-site is reduced, and site areas can be closed off quickly, leading to an accelerated project timeline.

Improved Quality Control

Manufactured in controlled factory environments, unitized wall systems are subject to rigorous quality control processes. This environment drastically reduces the variables that often lead to construction errors, ensuring that each unit is consistent with the next. The result is a product that meets high-quality standards before it even reaches the construction site, minimizing the need for time-consuming and costly rework.

Enhanced Safety

Construction sites can be hazardous places, with the risk of accidents significantly higher when multiple trades work in the same space. By reducing the amount of work done on-site, unitized wall systems lower the risk of accidents, creating a safer working environment for everyone involved.

Energy Efficiency

In today’s world, energy efficiency is more than just a buzzword—it’s a responsibility. Unitized wall systems often incorporate advanced materials and designs that improve buildings’ insulation properties and energy efficiency. This benefits the environment and translates to long-term savings on energy bills for building owners.

Sustainable Building

Sustainability is at the forefront of modern construction practices. Unitized wall systems contribute to green building practices by reducing waste through precise manufacturing. Additionally, the installation process’s efficiency helps achieve project sustainability certification, a significant advantage in the competitive construction market.

Incorporating Unitized Wall Systems into Your Projects

Adopting unitized wall systems requires a shift in thinking from traditional construction methods, with planning and coordination taking center stage. Early engagement with manufacturers is critical to ensure that the systems meet the specific needs of your project. However, the benefits of making this shift are clear and tangible, offering a compelling argument for their inclusion in modern construction projects.

The Bottom Line

For construction professionals and project managers looking to stay ahead in a competitive industry, mastering the use of unitized wall systems is not just an option; it’s a necessity. The advantages of faster installation times, improved quality control, enhanced safety, energy efficiency, and sustainability make a compelling case for their adoption.

Interested in learning more about how unitized wall systems can revolutionize your construction projects? Visit us at Glaziers Consulting for further insights and expert guidance.